The inclined casting technology is adopted for the wheel hub blank, which can realize rapid cooling and make the molecular structure of the wheel hub blank more compact. Meanwhile, during the cooling process, the potential energy of equipment turnover is used to increase the cooling of aluminum liquid in the process of heavy pressure, so as to further improve the mechanical properties of the spokes.

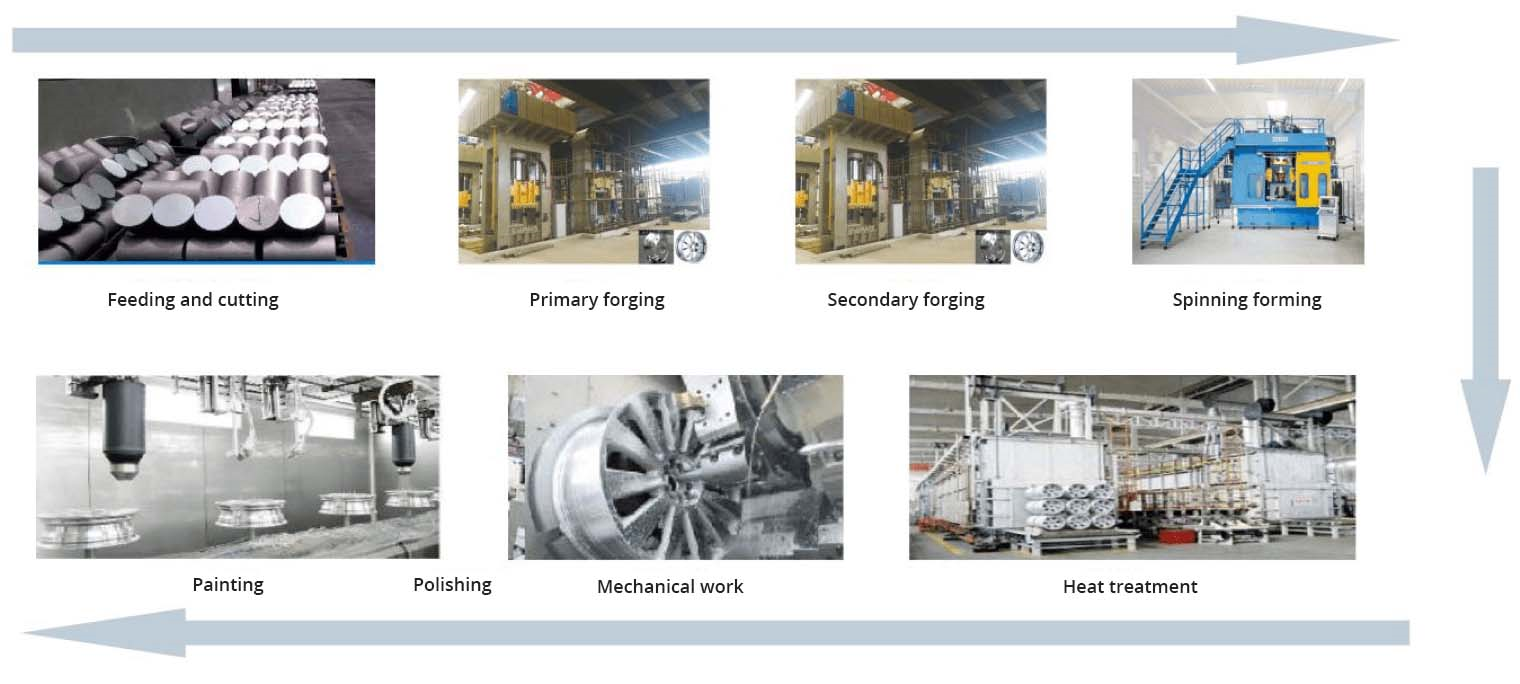

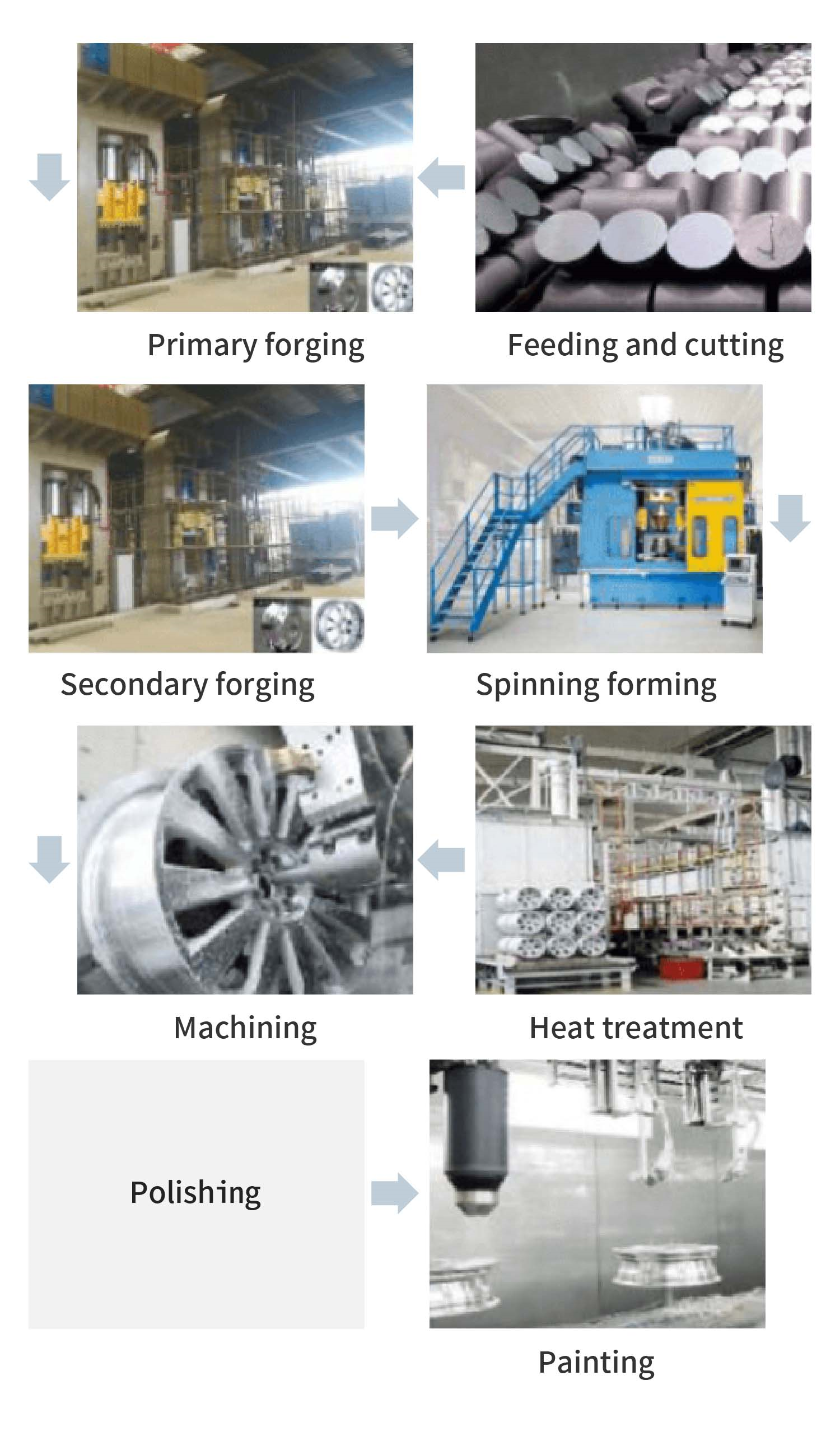

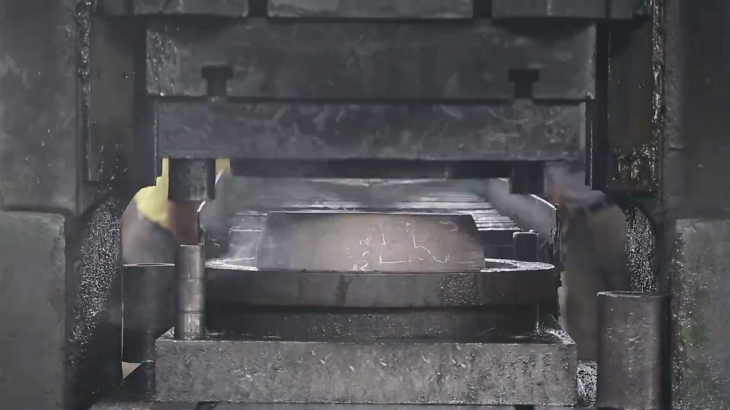

Forging process production flow

6061 aviation grade light aluminum alloy material 10000 tons forging and T6 heat treatment process makes the material structure more compact so as to achieve higher structural strength.

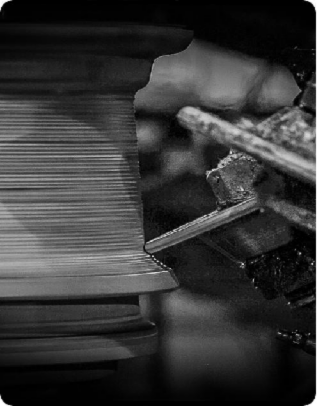

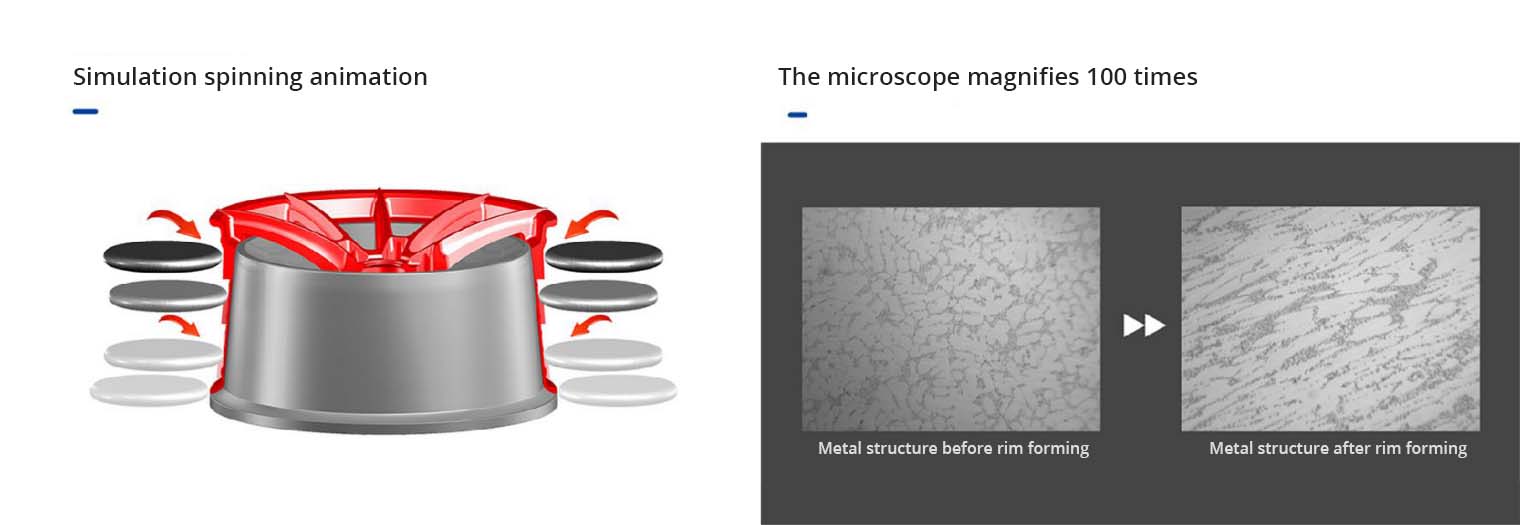

Spinning is a technology that produces plastic forming by rotating strong rolling. The billet is repeatedly extruded by strong force during the process of plastic forming, which makes the crystal structure inside the aluminum alloy more compact and the molecular structure more fibrous, so as to strengthen the key mechanical properties such as yield strength, tensile strength and elongation of the aluminum alloy material, and make the aluminum alloy material reach a better mechanical state. Combined with structural optimization, the lightweight and durable wheel hub is finally realized.

The preform is plastically formed under the action of spinning and drawing force, so that the crystal structure is further compact and fibrous, so that the mechanical properties of the material are stronger and the strength is further improved, so as to achieve lighter weight and durability.

The thin wall of the wheel is refined from top to bottom. The whole process of shaping the wheel is to improve the crystal structure of the aluminum alloy to be more compact, the molecular structure to be more refined and fibrous, and effectively improve the elongation, tensile strength and yield strength of the material.